Grupo Industrial UMO

For years, UMO has been an OEM supplier, specializing in exhaust systems and motorcycle seats. Currently, UMO has four business units:

· SEKI, focused on PU injection for industrial applications

· PREXA, focused on industrial painting

· FORMAPRESS, a partner focused on metalmechanic procedures such as machine pressing, stamping and press design.

· KIPO, UMO's B2C brand created in 2014 to focus on motorcycle performance exhaust systems

UMO's adaptability to clients' purposes and strategies is, without a doubt, one of the company's outstanding traits, giving value to each brand.

"Choices and design perception may change. Our design team is aware of this and is strong enough to provide each client plenty of options," Giraldo said.

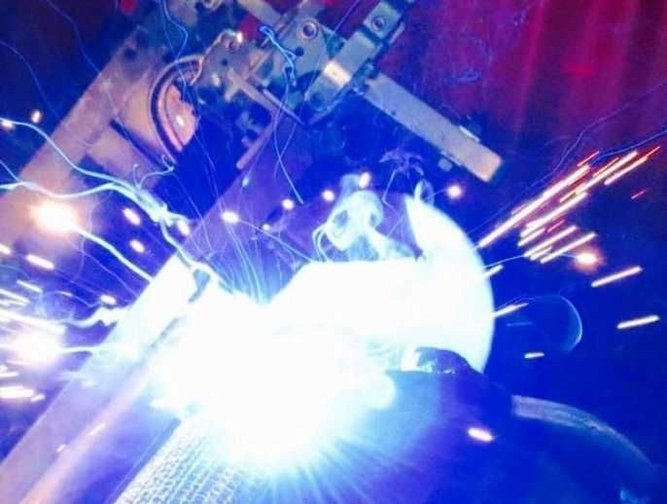

Precision technology

Manufacturing processes at UMO depend on a balance of automation and precision manual labor for component assembling. Automated welding and CNC machining are used to deliver exact results, according to every model's specifications. These resources provide accuracy in delivering the same chemical composition and stability to 35,000 to 40,000 motorcycle seats.

For management tasks, UMO relies on an ERP-SAP system, able to link different operations such as finances, payroll and logistics, among others.

"Automation in our most critical procedures support the company's growth rate," Giraldo said.

Key purveyors: steel and logistics

Stainless steel is a must for exhaust system manufacturing, and every material must comply with clients' fabrication demand. Because this material is scarce locally, UMO imports 304 and 436 type stainless steel from plants in Brazil, Mexico, Corea and Germany.

Another important partner for UMO is its local logistics supplier, a reliable ally to bring raw materials into the country on schedule.

Standard compliance and supplier certification

Global manufacturing companies demand their purveyors follow the industry's best practice standards. Some of UMO's global credentials include ISO/TS:16949 as well as compliance with General Motors SGM standards, Renault's ASES program and among others.

In order to meet such requirements, UMO passes these same demands onto its supply chain, and performs constant audits and evaluations to update standards and best practices. Some of UMO's suppliers have benefitted by obtaining ISO:9001 certification, particularly in regards to deployment of improvement programs such as Six Sigma and others resources, assuring quality in their production line.

"The market requires high technical standards; every procedure and material must provide traceability," the executive said.

KIPO: after-market performance exhaust systems

"One of our most important growth strategies is the development of KIPO, our aftermarket business unit," Giraldo said. KIPO was created in 2014, functioning as the only B2C business line for UMO Industrial Group. Currently, KIPO items are exported into the United States and Mexico. In the short to mid-term, KIPO products will also ship to Costa Rica, Ecuador, Peru and Chile; other efforts are also being carried out in Argentina and Guatemala. In the long term, UMO is considering a partnership with local enterprises in India and Thailand, since the company is already manufacturing equipment for Indian motorcycle brands.

This B2C venture promises to boost UMO’s interaction with the market on a much larger scale, dependent upon growth efforts.

Human resources

There are three main areas for collaboration between UMO and its staff:

1. A monthly improvement plan, which includes a policy to accept a monthly average of 45 to 60 suggestions from employees at any level. Typically, at least four or five suggestions are found viable by the company's management.

2. A Kaizen program for continual improvements, carried twice a year.

3. Support plans, offered by UMO, to its entire personnel for learning new skills, partnering with education institutions to provide special courses.

Environment and community

UMO Industrial Group invested in a new, eco-friendly painting plant able to generate zero residual chemicals. Costs of operations at this facility are 30 to 40 percent higher than traditional solutions, but UMO has made financing it a priority in order to avoid any negative impact on the environment. Residuals from welding processes are managed by a specialized local company.

UMO Industrial Group gives back to the community through organizations supporting education and proper nutrition for children in Medellin's most vulnerable communities. The company has also formed agreements with higher education institutions provide for twelve intern positions in UMO Industrial Group.

Planned growth and resources to achieve it

UMO's decision-makers understand the current economic developments and fluctuating oil prices, conditioning its growth according the success of its clients. Projections for the short term include a growth rate for the company that doubles Colombia's, meaning that the rate will still be a single figure.

Nevertheless, the company plans to double its total value by 2020. This goal is not far from being accomplished, once KIPO establishes itself in the entire continent, and completes plans to export to India and Thailand.

"Our dream of doubling the company's value can be accomplished with a strong exports operation. This is a long term effort," the executive said.