Automated Storage Solutions Create Value in Modern Manufacturing

At the start of every new year, people traditionally make resolutions for change. It’s often a time organisations seek to add value to their operations by finding new ways to lean processes, improve efficiencies, reduce costs and above all increase profits. This year, resolve to add value in 2014 by considering the value of time, space, picking, people and accuracy within current operations.

Value of time

How many minutes does it currently take to make an average pick and what would the impact of cutting that time in half add to your bottom line?

Kardex Remstar automated storage and picking solutions deliver items directly to the operator, drastically reducing travel and search time commonly associated with shelving. This allows the operator to spend more time picking, increasing overall productivity by 2/3.

Automated storage and picking solutions often only require one worker to handle the same volume due to the reduced travel and search time. More often, facilities are choosing to maintain current labour levels when implementing automated storage and picking solutions to increase picking productivity, resulting in higher picking capacities without additional labour.

Value of space

What is the value of additional floor space? The value of floor space varies depending on the activity occurring in that space.

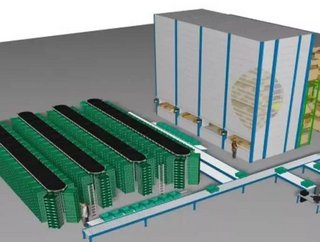

When compared to standard shelving, a Shuttle XP Vertical Lift Module (VLM) can save up to 85 percent of floor space. Eliminating aisle space required for shelving and utilising the complete floor to ceiling height provides organisations with a smaller footprint.

Implementing automated storage and picking solutions creates floor space for additional manufacturing or other value added activities.

Value of picking

Is picking one order at a time limiting picking operations? Workers picking one order at a time often find themselves walking several miles a day and visiting popular SKU locations multiple times.

Using an automated storage and picking solution for batch picking, one worker can fill multiple orders (called a batch) in just one rotation or cycle of the unit. Batch picking can easily be paused to fulfill hot picks immediately on demand.

Speed picking not only reduces bottlenecks in shipping or manufacturing but allows facilities to meet specialty demands.

Value of people

Do workers suffer from fatigue, are workers at risk of injury? All Kardex Remstar solutions operate on the goods-to-person principle, stored items are brought directly to the operator, eliminating reaching, bending, walking, twisting and lifting activities commonly associated with shelving.

This OSHA friendly work environment reduces worker fatigue and reduces risk of worker injury.

In addition to worker ergonomics, all units feature multiple safety systems. Light curtains, emergency stop buttons, automatic shutter doors and photo eyes ensure the safety of both workers and the stored items.

Value of accuracy

What is the true cost of a mispick? The cost of a picking mistake is typically calculated using the cost of the item and the additional shipping costs incurred.

Now, consider how much time is wasted returning the incorrect item to inventory and then picking, packing and shipping the correct item. There are additional hidden costs too; consider unhappy customers and the negative impact to your company reputation. All Kardex Remstar solutions can be integrated with light directed picking technology, increasing picking accuracy to 99.9 percent.

Whether the filing cabinet is overflowing or the warehouse is backed up from the holidays, implementing automated storage and picking solutions can increase profits and add value to operations.

Kardex Remstar automated storage and picking solutions can increase productivity, maximise floor space, increase throughput, protect workers and reduce mispicks. It’s all about putting value back into operations in 2014!

- Comau's Automation Solutions for Outside of ManufacturingAI & Automation

- How Intelligent Automation is Reshaping ManufacturingSmart Manufacturing

- Optimising back-office operations with AI in manufacturingAI & Automation

- Panasonic Connect’s Autonomous Manufacturing SolutionsAI & Automation